WE PROVIDE THE BEST QUALITY TRANSMISSION EQUIPMENT AND EXCELLENT SUPPORT SERVICE

Engineering Capability

We believe that quality should never come at the expense of affordability. That's why we strive to offer competitive pricing on our entire range of gearboxes and reducers, allowing you to maximize your investment without compromising on performance or reliability.

HOW IT ALL BEGAN

Applications

Motions Drive solutions are widely used in industrial applications where operating conditions, installation space, or load characteristics differ from standard designs.

Conveying & Material

HandlingIncluding long-distance conveyors, inclined systems, heavy-load material transport, and customized conveyor layouts. Non-standard designs are often required to address torque peaks, space limitations, or special mounting requirements.

Automation & Production Lines

Applied in customized production lines, special-purpose machinery, and automation systems where standard gearbox configurations do not match system layouts. Design focus includes mounting flexibility, integration with motors and control systems, and long-term operational stability.

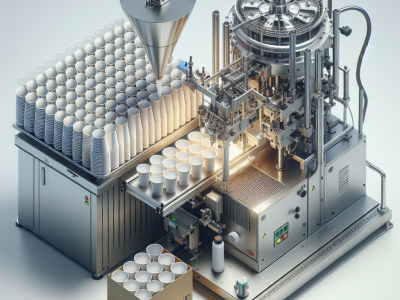

Packaging & Processing Equipment

Used in processing lines with specific speed profiles, intermittent operation, or cleanliness requirements. Customized gear ratios, housing designs, and shaft configurations are frequently required.

Heavy-duty & Special Machinery

Including mixers, crushers, agitators, and non-standard industrial equipment. These applications demand reinforced structures, high torque capacity, and engineering-driven design rather than catalog selection.

OUR HISTORY

To deliver top-notch gearboxes and reducers that exceed our customers' expectations in terms of performance, reliability, and value.

1985

Foundation and Vision

Our journey began in 1985, with a profound vision to revolutionize the industry by providing robust and reliable gearboxes and reducers. Our founder’s unparalleled expertise and progressive outlook positioned us for rapid growth and innovation.

1990: Laying the Groundwork

In our formative years, we focused on building a strong foundation with a dedicated team, robust R&D, and a commitment to excellence. We established our first manufacturing plant and began production, prioritizing quality and customer satisfaction.

Expansion and Diversification: 2000

As we entered the 1990s, our company expanded its product line to meet the growing needs of various industries. With diversification, we also extended our reach into international markets, reinforcing our presence as a global competitor..

2010

Technological Advancement

We have introduced more than 300 sets of precision instruments and equipment, such as HOFLER shaping gear grinding machine in Germany and the most advanced precision CNC lathe, machining center, precision worm gear grinding machine, CNC worm wheel grinding machine, gear hobbing machine, coordinate measuring instrument, gear detection instrument, etc. in China, so that the product manufacturing process and equipment are at the leading level in China. At the same time, the company took the lead in passing the ISO9001 international quality system certification in the same industry in China.

2024